With a full fabrication and machine shop capable of taking an idea to reality, Bulk has assembled a team of excellent fabricators with decades of experience. This team gives us the ability to create, customize or repair anything made of metal.

Extensive wear and tear from unforgiving conditions in the industries heavy equipment supports is common. With in-house reconditioning capabilities, Bulk is able to offer a more cost-effective option than supplying brand new.

Every job site has a unique set of heavy equipment needs. Whether it’s altering bucket teeth or building a specific attachment, we have the capabilities to modify any project to a specific application.

Utilizing advanced CAD and CAM software, we’re able to engineer full-service creative solutions. Successfully taking ideas from napkin sketch to final product is just another day in the shop at Bulk.

We provide a large fleet of Wheel Loaders to our customers. With this comes the need to inventory, maintain, and oftentimes completely rebuild a large quantity of Wheel Loader buckets. To keep our overall cost of ownership as low as possible, we’ve dedicated a section of our fab shop to rebuilding buckets. Being able to do this in-house has allowed us to find various ways of extending the life of these buckets by using specialized materials and strategically placing additional metal in high-wear areas.

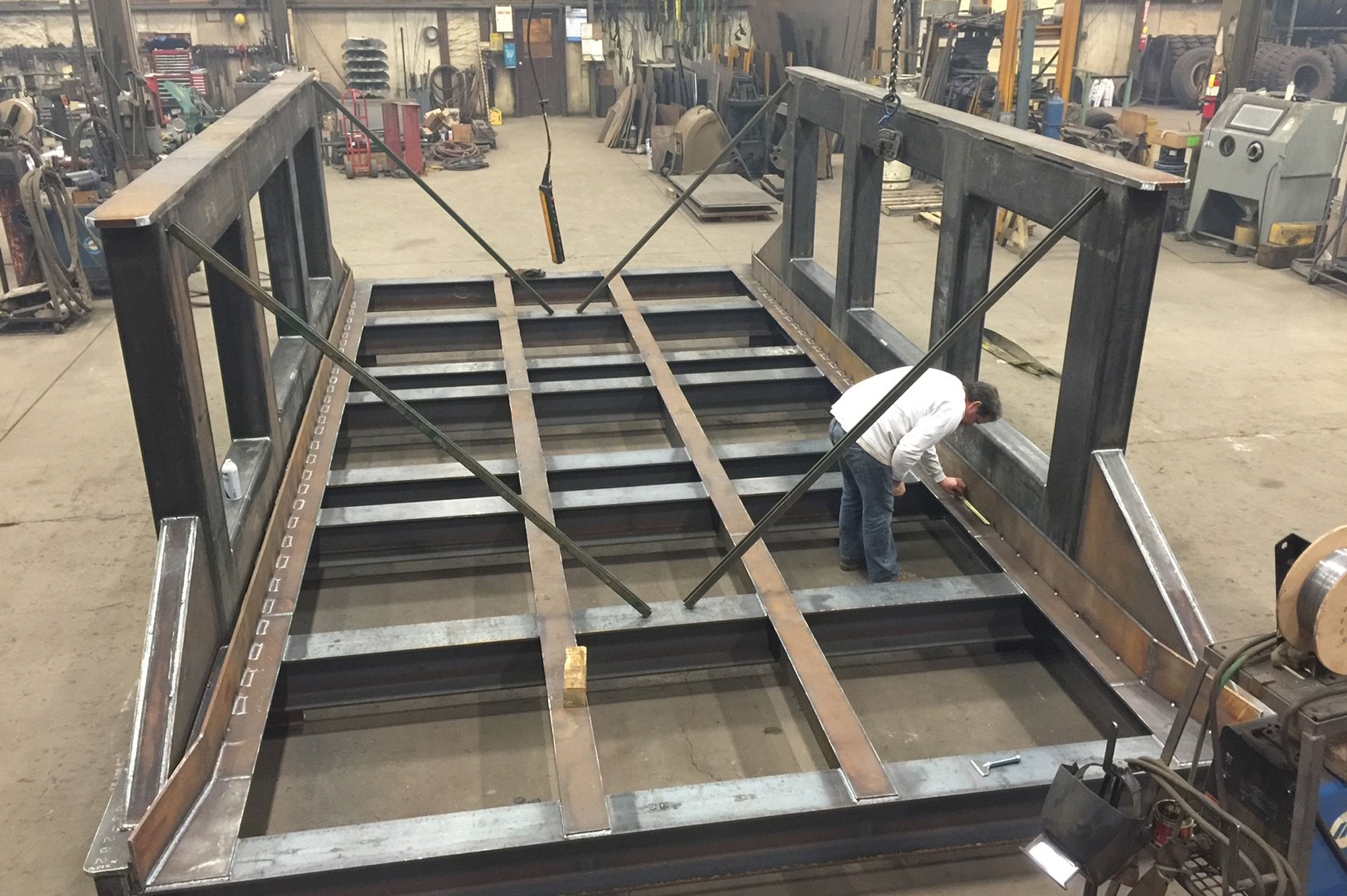

Identifying ways our customers can gain efficiencies is an important part of what we do. Here we added sideboards to this A60 dump body so our customer can haul more of their light material in each load. The factory tailgate was also modified and the hinge point raised to fit the new shape of the bed.

Window guarding provides operators protection from material coming into contact with the cab windshield. Because it’s not always an option to source OEM or aftermarket solutions, the Bulk fabrication shop team builds our own solutions to meet the requirements and timelines of our customers.

A customer who we supply a Transporter System to was having problems using their rail system to transport large rolls from their mill to the roll shop. Because of the adaptability of the Transporter System, we were able to design and fabricate an additional pallet that could handle all their various roll sizes. This gave them the flexibility to transport their rolls using the elevating transporter. Now they are not dependent upon the rail system and the roll shop has what they need when they need it.

When our customer’s safety department asks us to build them a heat shield to deflect the heat of their product away from the tires on one of our reach stackers, our fab shop delivers.

We provide a large fleet of Wheel Loaders to our customers. With this comes the need to inventory, maintain, and oftentimes completely rebuild a large quantity of Wheel Loader buckets. To keep our overall cost of ownership as low as possible, we’ve dedicated a section of our fab shop to rebuilding buckets. Being able to do this in-house has allowed us to find various ways of extending the life of these buckets by using specialized materials and strategically placing additional metal in high-wear areas.

Identifying ways our customers can gain efficiencies is an important part of what we do. Here we added sideboards to this A60 dump body so our customer can haul more of their light material in each load. The factory tailgate was also modified and the hinge point raised to fit the new shape of the bed.

Window guarding provides operators protection from material coming into contact with the cab windshield. Because it’s not always an option to source OEM or aftermarket solutions, the Bulk fabrication shop team builds our own solutions to meet the requirements and timelines of our customers.

A customer who we supply a Transporter System to was having problems using their rail system to transport large rolls from their mill to the roll shop. Because of the adaptability of the Transporter System, we were able to design and fabricate an additional pallet that could handle all their various roll sizes. This gave them the flexibility to transport their rolls using the elevating transporter. Now they are not dependent upon the rail system and the roll shop has what they need when they need it.

When our customer’s safety department asks us to build them a heat shield to deflect the heat of their product away from the tires on one of our reach stackers, our fab shop delivers.

Steel Mill Application (SMA) Front-End Loaders have the base of a tried and tested design with a reinforced frame, cab, and components in order to operate and handle molten steel and blast furnace slag. Designed to protect the operator and reduce the risks when handling molten slag, the front-end loader cab is fitted with impact- and heat-resistant glass. There is also a closed HVAC system to prevent the introduction of gases created when handling the molten slag.

The Straddle Carrier increases productivity for the customer by eliminating the use of flatcars to transport slabs throughout the mill. This asset decreases the number of times the slabs are handled by providing the ability to drive directly over top of the slabs, picking them up, and transporting them directly to the location of the customer’s needs. These machines can also pick and sort through slab piles, selecting specific slabs for their orders, and achieving just in time delivery.

The Pot Carrier is constructed to lift and carry a slag pot designed to the specific capacity of the steel maker’s furnace. It also provides the operator with additional safety features in an effort to further reduce the hazards and to allow for ease of handling and transporting the slag pot to an engineered dumping station.

The prime mover, or tractor, utilizes a scraper design and then updates the operator’s cab with the ability to face in the direction of operation. This improves visibility and increases productivity.

With a modified or purpose-built spreader replacing the container spreader, we hang magnets for slab handling and C-hooks or coil tongs for coil movements. When handling hot slabs, purpose-built slab tongs can withstand temperatures up to 1,100 degrees F are attached. Typical lifting capacity under the lifting device can range from 35 to 50 tons depending on attachment weight and configuration. However, there are manufacturers that are now building Reach Stackers with significantly more lifting capacity. As capacity goes up, maneuverability due to increased wheelbase goes down.

The first Continuous Transport System Bulk supplied to a customer was in 1999. This replaced multiple heavy-duty tractors and trailers along with the labor support required to operate the trucks. Not only were we able to save our customer significant expense by moving from multiple trucks, trailers and drivers to one single machine with one operator, but we were also able to decrease the carbon footprint by burning significantly less fuel while accomplishing the same or more productivity.