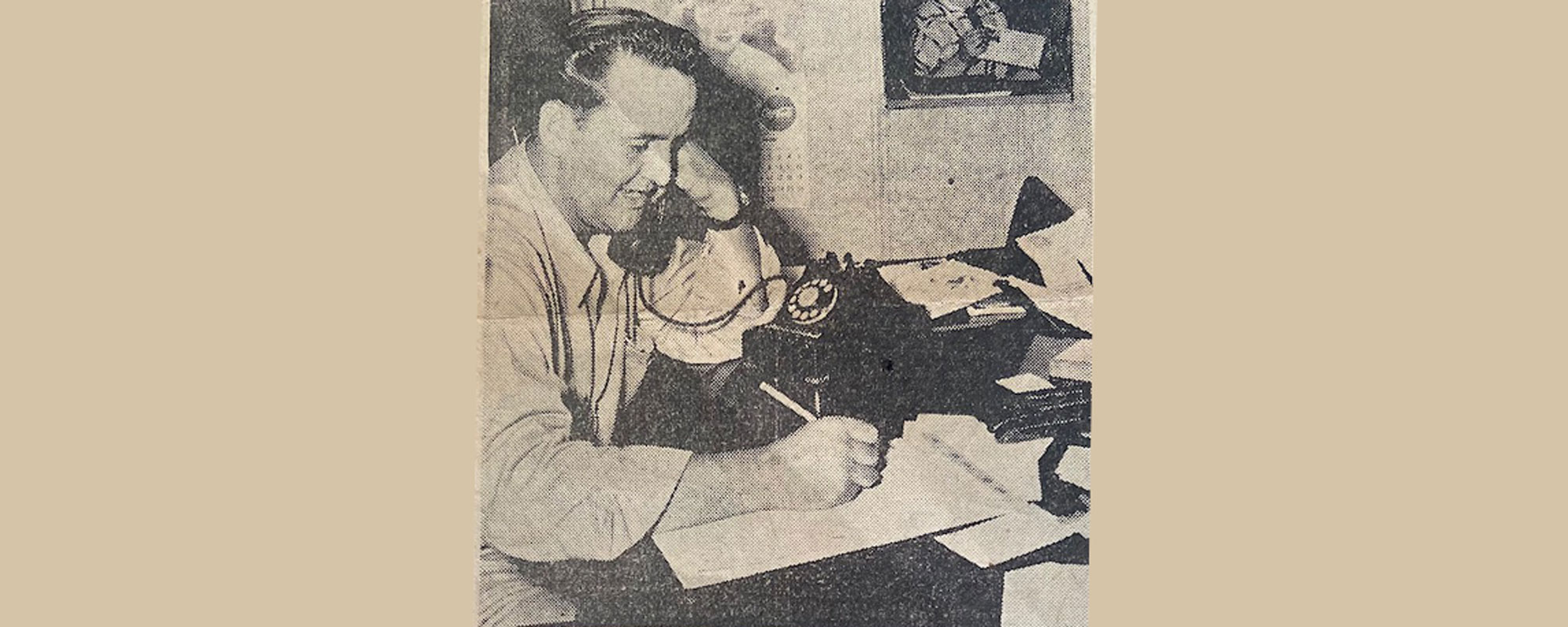

In 1936, when someone wanted a little dirt moved, they called 16-year-old Leonard Brown. Using his old-time sand buggy, he’d move a yard of dirt at a time until the job got done. Fast forward 12 years, and Leonard had grown from a single sand buggy to an established business, Brown Trucking Co., with a fleet of 25 heavy-duty trucks.

Clearly, Leonard Brown wasn’t afraid of hard work, but what made him special was his ability to have a vision and think beyond limitations to reach it. This was evidenced by the fact that his fleet was one of the first in the nation to operate under radio control.

Always looking for cost and time efficiencies, pioneering with radio allowed Leonard and his team to shift equipment from one job to another without needing a trip or phone call to the office first, virtually eliminating empty trucks just sitting around.

Communication also increased exponentially, giving the truck drivers and operators of equipment a way to be in touch. In the event of breakdowns or flat tires, assistance was able to be dispatched almost instantly. And when on the job, a grader, scraper or crane operator could talk with Leonard while he was at the office and get specific instructions.

This type of forward thinking is a mindset that’s been passed from generation to generation, and one that still fuels the Bulk business model today.

Steel Mill Application (SMA) Front-End Loaders have the base of a tried and tested design with a reinforced frame, cab, and components in order to operate and handle molten steel and blast furnace slag. Designed to protect the operator and reduce the risks when handling molten slag, the front-end loader cab is fitted with impact- and heat-resistant glass. There is also a closed HVAC system to prevent the introduction of gases created when handling the molten slag.

The Straddle Carrier increases productivity for the customer by eliminating the use of flatcars to transport slabs throughout the mill. This asset decreases the number of times the slabs are handled by providing the ability to drive directly over top of the slabs, picking them up, and transporting them directly to the location of the customer’s needs. These machines can also pick and sort through slab piles, selecting specific slabs for their orders, and achieving just in time delivery.

The Pot Carrier is constructed to lift and carry a slag pot designed to the specific capacity of the steel maker’s furnace. It also provides the operator with additional safety features in an effort to further reduce the hazards and to allow for ease of handling and transporting the slag pot to an engineered dumping station.

The prime mover, or tractor, utilizes a scraper design and then updates the operator’s cab with the ability to face in the direction of operation. This improves visibility and increases productivity.

With a modified or purpose-built spreader replacing the container spreader, we hang magnets for slab handling and C-hooks or coil tongs for coil movements. When handling hot slabs, purpose-built slab tongs can withstand temperatures up to 1,100 degrees F are attached. Typical lifting capacity under the lifting device can range from 35 to 50 tons depending on attachment weight and configuration. However, there are manufacturers that are now building Reach Stackers with significantly more lifting capacity. As capacity goes up, maneuverability due to increased wheelbase goes down.

The first Continuous Transport System Bulk supplied to a customer was in 1999. This replaced multiple heavy-duty tractors and trailers along with the labor support required to operate the trucks. Not only were we able to save our customer significant expense by moving from multiple trucks, trailers and drivers to one single machine with one operator, but we were also able to decrease the carbon footprint by burning significantly less fuel while accomplishing the same or more productivity.